Neyagawa Plant

Plant establishment: 1978 Site area: 4,932m² Plant area: 5,500m²

Certification: ISO9001, ISO14001

The history of SAN-AI, which has “challenged the possibilities of paper”, is also a history of “development of original processing methods”. Ever since the founding of SAN-AI, the goal of Neyagawa Plant has been to serve as an arm of work processes and effect ideas for improving the usability of paper from the viewpoint of customers. Our attitude is that there is no paper or film that cannot be cut, and if we encounter something that cannot be cut, to accept the challenge. There is no more to be said. We wish for nothing more than customer satisfaction. We will bring together our total capabilities in an effort to respond to everybody's expectations.

Equipment at Neyagawa Plant

-

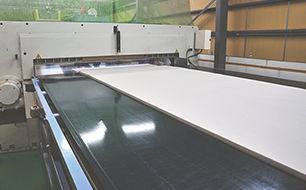

Sheet Cutter 35

Maximum base paper width1300mm

For processing flat leaves of adhesive paper for the separator, etc. -

Pressing,Seal processing 134

Maximum product dimensions 200mm×150mm

Inside the cleanroom -

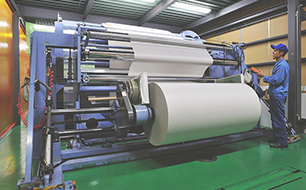

Wide, large-size slitter 32

Original fabric maximum width1650mm

Maximum products finishing diameter Ø2000mm -

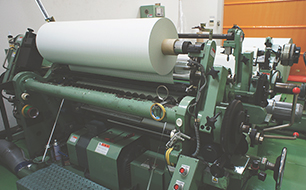

Double axis slitters 28

Original fabric maximum width1280mm

Original fabric maximum width Ø550mm -

Single axis slitters 13

Original fabric maximum width1280mm Minimum product width 12mm

Float winding -

Single axis slitters 15

Original fabric maximum width1380mm

Minimum product width 20mm -

Continuous pressing,Seal processing 117

Maximum product dimensions 240mm×240mm

(155mm×155mm When die is attached)

Laminating Pressing Stripping

Continuous rolling or cutting is possible

Inside the cleanroom -

Single shot pressing 141

Scudding press Product maximum width 700mm×500mm

Various materials -

Pressing with image recognition 128

Printing film, etc. can be pressed upon positioning by CCD camera. Product maximum width 500mm×450mm Inside the cleanroom

-

Guillotine 25

Product maximum width and flow 1120mm×1260mm

Inside the cleanroom film For dedicated use with clean paper -

Sheet Cutter 34

Product maximum width and flow 1150mm×800mm

Inside the cleanroom -

Double axis slitters 58

Original fabric maximum width 1280mm Original fabric maximum width Ø600

High pressure room -

Guillotine 100

Large-die drum cutting machine and coupled cutting machine

Maximum width 2800mm -

Drum cutters 100

Product maximum width 2800mm×6500mm

-

IPA-10T 154

Material width within 340mm Product size within 290mm x 245mm

Roll material punching equipment.

Positioning punching processing using a camera is also possible.