Neyagawa No.2 Plant

Plant establishment: 2003 Site area: 2,301m² Plant area: 4,080m²

Certification: ISO9001, ISO14001

If Neyagawa Plant is the primary facility of SAN-AI in terms of scale and equipment, Neyagawa No. 2 Plant is a "strategic plant" with an eye on future markets. Moving from the level of simple cutting, this plant has helped us evolve into a "proposed development-based processing" maker. In recognition of this stance and our work record, orders for processing of non-paper materials such as film and nonwoven fabric have increased. Orders originate from the light electrical appliance and IT sectors, in which absolute precision is demanded in products. To respond to such demands, this plant has installed a cleanroom with a view to properly responding to the sophisticated requirements of customers. Our customer's needs are becoming increasingly diversified together with the times, however, no matter what kind of requirement is voiced, we are confident that we can give a definite response.

Equipment at Neyagawa No.2 Plant

-

Surface type single axis slitter 162

Original fabric maximum width 1250mm

Product maximum diameter 550㎜

Machine introduced in July 2023 -

Single axis slitters 104

Original fabric maximum width1400mm

Original fabric maximum width Ø600mm -

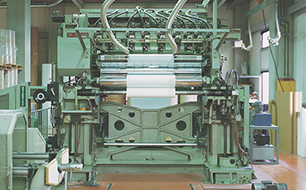

Wide, large-size slitter 37

Original fabric maximum width1750mm

High-speed winder with float winding capability -

Traverse processing 94

Processing length can be extended through conducting traverse processing

Inside the cleanroom -

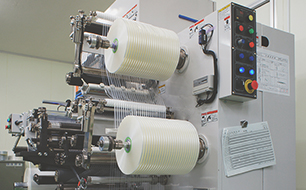

Double axis slitters 98

Original fabric maximum width1700mm

Various film slitting Inside the cleanroom -

Sheet slitter 103

Slitting of emboss carrier sheet and other thick sheets Slitting possible from width of 8mm Inside the cleanroom

-

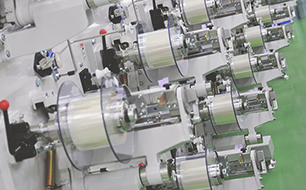

Micro slitters 26

Original fabric maximum width780mm

Micro slitting of cover tape and films Inside the cleanroom -

Other slitting/battery uses

Rechargeable battery separator slitting

Inside the cleanroom -

Other slitting/For metallic foil and RFID

RFID film (capable of inspecting slit position) and metallic foil slitting Inside the cleanroom

-

Micro slitters 109

Slitting of cover tape and various film

Inside the cleanroom -

Laminating 99

Capable of laminating and slitting protective film on HCPET and other films Capable of slitting Original fabric maximum width1250mm

Inside the cleanroom -

Other slitting/Adhesive products

Original fabric maximum width800mm