Tondabayashi Plant

Plant establishment: 1989 Site area: 3,279m² Plant area: 3,153m²

Certification: ISO9001, ISO14001

Tondabayashi Plant fully operates as an authoritative facility in the realm of flat paper centering on lamination and punching. Possessing equipment for performing cutting - interleaving paper - punching - packaging, it responds to various needs. Mainly working on “paper”, its current customers include major electrical machinery makers and major paper manufacturers, however, it has also installed a cleanroom to address increasingly common needs for processing film materials into members for use in precision instruments. Tondabayashi Plant has established a unique and rigorous inspection setup and installed inspection equipment, and it also takes the utmost measures with respect to its quality control setup.

Equipment at Tondabayashi Plant

-

Rotary cutters 63,64

Original fabric maximum width 左1700mm 右1400mm

Maximum paper density 600g/m² -

Thomson 85

Maximum base paper dimensions 740×1020

-

Paper laminating 80

3-sheet simultaneous laminating machine

Maximum product thickness 6mm -

Inspection and assembly work

Quality inspection and product inspections inside the cleanroom

-

Continuous pressing,Seal processing 76

Laminating, pressing (2 points), stripping functions, winding and flat paper finishing

Maximum width 230mm Inside the cleanroom -

Single shot pressing 65

Maximum dimensions 800mm×600mm

Maximum load 80t -

Guillotine 72

Cutting machine with paper feed and removal mechanism

-

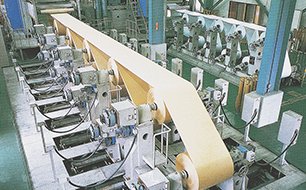

Small roll 70

Fully automated small roll machine

-

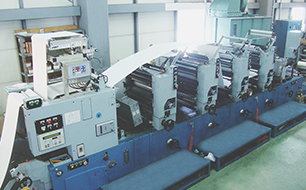

Machine for making albums and pharmacy bags 116

Mounts for printed albums, film pharmacy bags, etc.

-

Thomson 152

Punching pressure 300t Material thickness 0.1~2mm

Product size Minimum 400mm x 330mm Maximum 1,060mm x 740mm

Product and waste can be separated and taken out.