Laminating

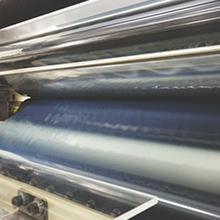

Laminating refers to the process whereby materials are superimposed onto other materials through the medium of adhesive layer. In most cases, the same type of material is laminated to increase thickness, or different materials are laminated to give separate functions on the front and rear sides. Sometimes, 2 or more materials are laminated in a single process, or laminated materials undergo further laminating, so the number of laminated materials (layers) is not necessarily limited to 2.

-

Laminating Methods

Laminating is conducted by the following 4 methods:

・Method where adhesive is applied to one of the materials and this is laminated to another material.

・Method where melted resin is dripped and the materials to be laminated are pressed down from both sides of this.

・Method where the materials are laminated after heating them or inserting hot-melt material between the materials to melt them.

・Method where lamination is conducted using materials that are pre-treated with adhesive (adhesive layer). -

Laminating in SAN-AI

SAN-AI can implement lamination using the following equipment.

Method where adhesive is applied to one of the materials and this is laminated to another material.

Many products are used in the state they are following lamination.

・Processing machine 1 (sheet+sheet Paper materials)

Numerous sheets of paper material are layered and set in separate places.

One sheet each is delivered from the set locations while glue is applied to one of the sheets; the glued sheet is laminated onto materials delivered from the separate places, and the materials are inserted between rolls to perform the lamination. In the case of paper materials, this process targets thick products (referred to as liner or board paper).

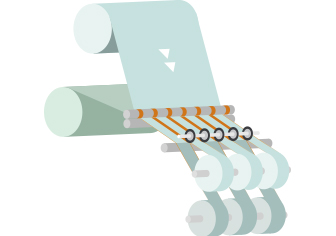

It is also possible to simultaneously laminate three sheets. Moreover, laminated objects can be set with other materials and laminated again, thereby making it possible to make multi-layered products.・Processing machine2 (roll+roll Paper and film materials)

Separate rolls of materials are set and delivered by drawing out.

Glue is applied to one of the sheets; the two sheets are superimposed, and then they are pressed between rolls to perform the lamination. It is also possible to simultaneously laminate three materials.

The materials that can be processed are mainly paper and film. With paper, film or other materials, items that repel glue or let the glue permeate are not very suitable, although some materials can be worked by selecting the type of glue and so on.

Concerning the type of finish following lamination, it is possible to select winding roll finish, sheet cut finish, or accordion-fold finish.

Since glue is applied using an object like a rubber printing plate (glue plate), it is possible to intentionally make glued and unglued parts by altering the pattern of the plate, and various patterns can be used according to the objective. Accordingly, the glue plate as a rule is made for each job (with the desired pattern).

Moreover, before applying glue, up to 4 colors can be printed on the front and rear sides of one of the materials, and punching can also be performed before and after the gluing.Method where lamination is conducted using materials that are pre-treated with adhesive (adhesive layer)

Following the lamination, many materials are peeled in other processes.

・Processing machine 3 (roll+roll Film material)

Material of rolls are set and each material is drawn out.

The adhesive face of the material having the adhesive, and the other material (hereafter referred to as the substrate), are pressed and laminated between a rubber rolls; hence this method is predicated on one of the materials being treated with adhesive.

The laminated product is wound onto a roll to finish, and slitting can also be performed when doing this.

Sometimes, the adhesive material has a layer known as a separator for protecting and concealing the adhesive face, but processing can also be performed while peeling off the separator.

In other cases, protective material is sometimes affixed to the substrate, but again, processing can be conducted while peeling this off.

For example, assuming that the substrate side as A+B and the material with adhesive as C + D, it is possible to laminate A+D while peeling off B and C.

Concerning adhesion, there are various types of glue and various levels of adhesive force.

If the adhesion is too weak (i.e. easy to peel), SAN-AI cannot perform lamination; however, conversely, if the adhesion is too strong (i.e. it is hard to peel), troubles will arise in later processes. So it is necessary to select the adhesive materials according to the desired objective. If nothing is specified about the type of material used on the adhesive face, SAN-AI can offer selected samples for you to confirm before deciding on the material.

Since the processing environment is a clean room, it is not possible to bring paper materials, items that are regulated by our company, or other foreign substances that fall off or scatter or that adversely affect the clean environment.・Processing machine4 (roll+roll Paper and film materials)

The principle is almost similar as that of processing machine 3, however, the width of materials that can be set is narrower than in the case of processing machine 3, and simultaneous slitting cannot be performed either.

Concerning the method of finishing, the laminated product can be wound onto a roll, or it can be cut into sheets.

The processing environment includes a general environment and clean room, which can be used according to the materials being processed.

This machine can be linked to punching equipment to conduct lamination before or after punching.

| Protective film | Laminating 99 |

|---|---|

| Adhesive tape | |

| Paper laminating | Paper laminating 80 |